Terminology and Glossary

Bezel

Bezel

See Rim.

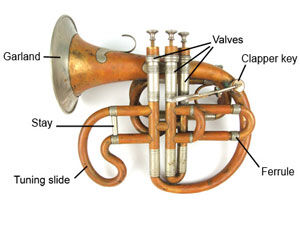

Clapper key

A key found on early 19th Century valved trumpets, cornets and cornopeans to enable an easy execution of trills, invented by McFarlane in 1834. See 10.11 for an example in the collection.

Crook

A length of tubing used to change the pitch of a brass instrument, found on valved and valveless instruments.

Ferrule

A sleeve fitted over the joint between two sections of tubing.

Garland

Annular strip of metal fixed to the outside of the bell of some brass instruments at the rim.

Garnishing

Decorative ferrule.

Gusset

Triangular section of metal inserted into the sheet of metal of a bell before it is formed, to provide extra expansion and ease of forming.

Knuckle

Small piece of tubing, usually angled, connecting the valve casing to other tubing.

Leadpipe

The first section of tubing of a brass instrument, extending from the mouthpiece receiver to the next joint. This is usually integral to the main body of the instrument and usually tapers, unless it is equipped with a tuning slide.

Rim

Ring of metal, usually semicircular in cross-section, added to the outside edge of a brass instrument bell to provide rigidity.

Shank

Straight piece of tubing for an instrument, such as a trumpet, fitting into the instrument at one end and receiving the mouthpiece or tuning bit at the other. See 10.11 for an example in the collection.

Slide

A section of airtight telescopic tubing.

Springs

On brass instruments with piston valves, springs are used to return the piston to its natural position, found on top or underneath the piston, inside the casing. Springs are also used to facilitate the water key.

Stay

Component of folded or coiled brass instruments which strengthens their structure by rigidly connecting two parallel or nearly parallel sections of tube.

Touchpiece

A circular button on top of the piston which is pressed to operate the valves.

Tuning slide

Airtight telescopic joint used to vary the length of the instrument and thus alter the pitch of the notes that can be sounded.

Valve

Mechanical device to channel air into different lengths of tubing, thereby changing the instrument’s harmonic series and making more notes available to the player.

Piston valves are represented in items 6.4 - 6.11 in the collection. The two main types of piston valves are Stölzel and Périnet.

Heinrich Stölzel first applied valves to a horn in 1814 and patented his design in 1818 in Vienna. François Périnet invented his type of piston valve in 1838 and patented it the following year.

With Stölzel valves, the main tubing enters the piston from below (as can be seen clearly in the cornopean by Wigglesworth, item 6.11). With Périnet valves, the main tubing enters from the side.

In both systems, the inlet tubing is positioned on a different level to the outlet tubing. The piston is held at rest by a spring, which is placed either on top (top-sprung) or below (bottom-sprung) the piston.

It is the Périnet valve which has become the standard for trumpets in most countries, except in Germany and Austria where rotary valves are favoured.

Water key

Key used to release water from the instrument. They are most often located at the first 180° bend in the tubing. See item 7.7 for an example in the collection.