Robotic Arm

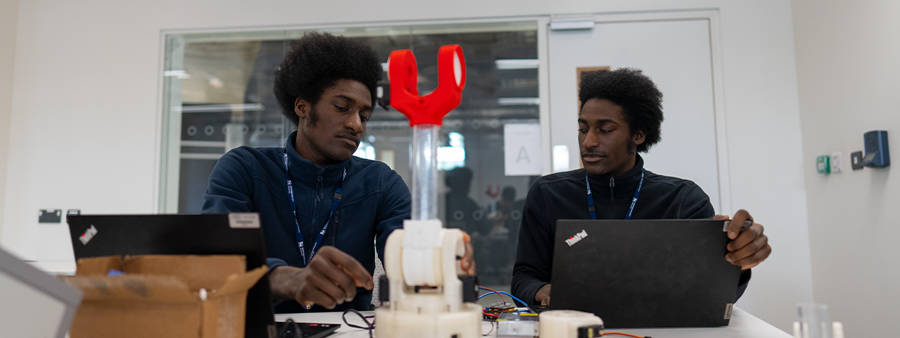

Team Cyber Grip

Teammates Jonathon, Richard, and William are Cyber Grip – a group of BSc (Hons) Computer Science students . They have created a robotic arm which they hope could be used as a concept to assist those in the medical field.

Give us a brief overview of your project

Our project is a robotic arm, which is designed to be of use in the healthcare field, in places where it is financially or socially challenging to get the kind of machinery needed to operate on people. We have created a concept that theoretically could be used in war zones where medical assistance is stretched.

What made you want to develop this idea?

We brainstormed our initial ideas, but we all agreed on a robotic arm. We thought developing this would be quite a challenge, which we knew would be fun.

Why is there a need for what you’re creating

We understand the risk of infection can be high when medical operations occur, so we wanted to lower that. We wanted to create something that can assist the work of a medical professional and even help with precision when it comes to incisions in operations, the arm would also be able to be controlled through the internet, allowing for somebody to control it on the other side of the world

Can you explain about the kind of equipment you are using, and how you are creating the physical product?

We have an Arduino board and 12v power supply, stepper motors – which help with controlled movement of the arm, and a computer to control it from. We sourced most of our technical parts online, but we made all of the parts ourselves. We can access 3D printers on campus, so we designed and printed the base and arm ourselves.

We had researched how big the arm should be; these ranged from really huge models to smaller 6-inch designs which you could put on your desk. We’ve gone for a slightly bigger model than 6 inches for our prototype, so you can still see it in action. To 3D print each part, it typically took around two days.

The design itself was already set out based on what a robotic arm should typically look like to function, so we made it our own regarding the code.

What challenges have you had to overcome?

We struggled with making the gears strong enough to support the arm so that it could move. We are currently considering using more durable material, which should solve this; alternatively, we could also play around with the sizes of the gears. It’s a lot of trial and error – but we’re just experimenting with what we can to make it work.

Are you excited for Innovation Festival?

Yes! We’re looking forward to the atmosphere on the day, meeting new people and connecting with them, and showing off our project. We also hope to win the main prize – we'll see how it goes!